4 Inch Backflushing Valve For Irrigation System

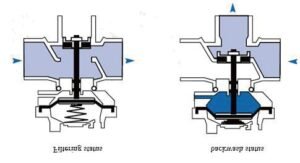

A fully automatic backwash filtration system dedicated hydraulic control valve, driven by the pressure of the pipeline system, can automatically carry out two-way switching, to achieve an automatic backwash filter. The simple structure and high reliability ensure long-term, stable operation without maintenance. The diaphragm drive structure requires only a short stroke to smoothly change the flow of water, close the inlet when the backwash port is open, and vice versa. Avoid filter overflows or water mixing with wastewater.

Additional information

| Interface type | 4 inch |

|---|---|

| Max working pressure | 0.7-10bar |

Product Details:

Simple structure, easy installation, save investment in ultra-strong hydraulic performance, work conversion frictionless high reliability, moving parts run smoothly anti-chemical corrosion materials, suitable for a variety of media water flow rapid, high backflushing efficiency.

- Hydraulically drive the diaphragm control valve.

- Unique plastic valve core assembly design, strong sealing, and corrosion resistance.

- The valve travel is short, and the flow changes smoothly and smoothly, avoiding the mixing of clean water and sewage.

- Valve body PA material design, corrosion resistance, acid and alkali resistance, long service life.

- The drive can be removed independently for easy online inspection and maintenance.

Parameters

Standard pressure level:10 kgf/cm²

Minimum operating pressure:1.0 kgf/cm²

3”-35 square/hour, plastic bayonet

How it works

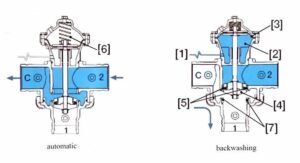

Take the straight-through flow control valve as an example: when the policy filters the working state, the inlet and outlet are connected, and the water flow is moving forward. When the external pressure water【1】into the diaphragm control cavity【2】, pressure increases, diaphragm【3】drive valve core assembly【4】up into the upper seat【5】, the inlet is closed strictly, at this time the sewage outlet and the outlet, the water flow back from the outlet to the sewage outlet into the backwash state. When the water in the control cavity is discharged, the pipe water pressure and spring elasticity【6】work together to bring the valve core【4】assembly back to the lowerseat【7】of the sewage outlet, the sewage outlet is closed and strict, and the control valve returns to the filter mode.

Application

The backflushing valve is applied to an automatic backflushing filtration system with at least two side-by-side filtration units, i.e. during the backflushing process, clean water filtered by one filter unit is used as flushing water from another filtration unit.

When the hydraulic signal from the controller is received, the backflush valve changes the flow of water: close the inlet, open the drain, filter the clean water through the other filtration unit into the unit for flushing, and discharge the flushing water through the drain.