The commonly used fertilization methods mainly include differential pressure fertilizer tank, venturi fertilizer, gravity self-pressure, pump suction, pump fertilization method, etc.

- Differential pressure fertilizer tank fertilization method

A differential pressure fertilizer tank is a fertilizer spreading equipment widely used in the field. It can be found everywhere in orchards in many countries, and it is also widely used in greenhouse vegetable and field production in China. The differential pressure fertilizer tank consists of two thin pipes (bypass pipes) connected to the main pipe. A control valve (ball valve or gate valve) is set between the two thin pipe contacts on the main pipeline to produce a small pressure difference (1~2 m water pressure), so that part of the water flows into the fertilizer tank, and the inlet pipe reaches the bottom of the tank. After the water dissolves the fertilizer in the tank, the fertilizer solution enters the main pipe through another thin pipe, bringing the fertilizer to the crop root zone. Differential pressure fertilizer tank fertilization is a method of fertilizing according to the quantity, and the concentration of fertilizer flowing out at the beginning of fertilization is high, and as fertilization progresses, the fertilizer in the tank becomes less and less, and the concentration becomes thinner and thinner.

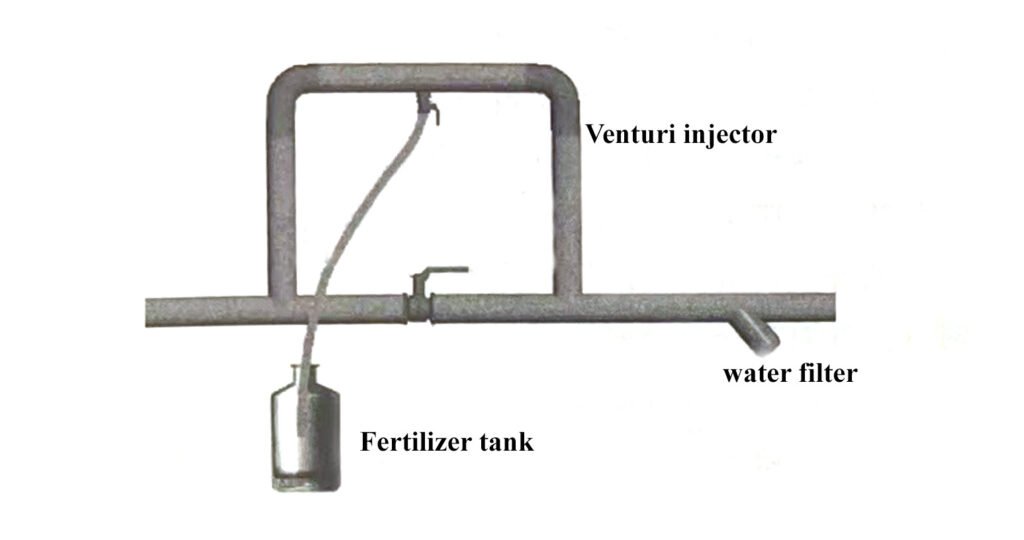

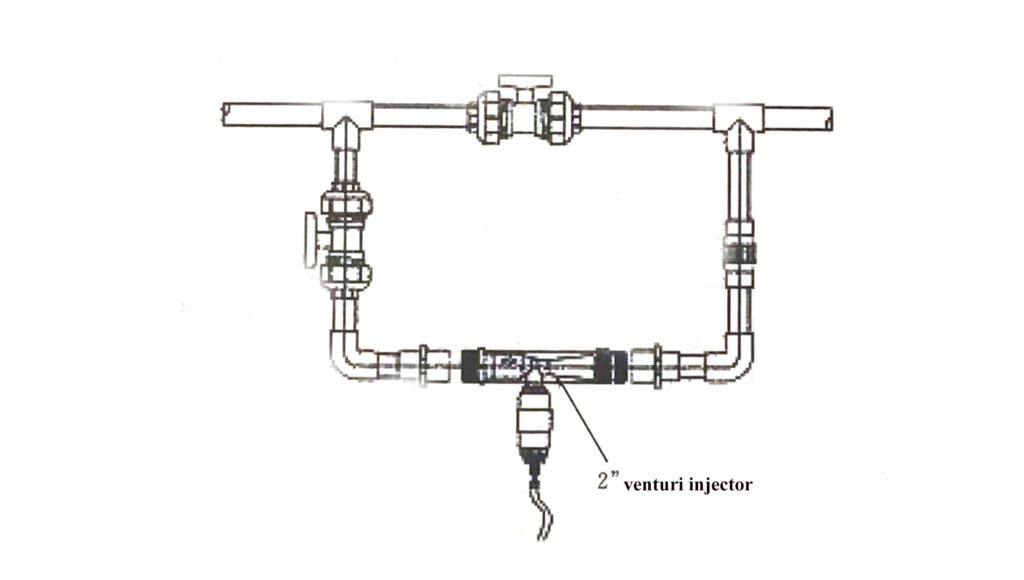

- Venturi fertilizer injector fertilization method

Like fertilizer tanks, venturi fertilizers are widely used in irrigation fertilization. The Venturi fertilizer applicator allows proportional fertilization and maintains a constant nutrient concentration during irrigation. When water flows through a pipe that gradually decreases from large to small and then gradually grows from small (venturi throat), the flow velocity increases and the pressure drops as the water flows through the narrow part, creating a pressure difference between the front and back. When there is an inlet of a smaller diameter pipe in the throat, negative pressure is formed to draw the fertilizer solution from an open fertilizer tank through a small diameter thin tube. The Venturi fertilizer spreader is made according to this principle.

Venturi fertilizer injectors are made of corrosion-resistant materials. The injection rate of the Venturi fertilizer depends on the amount of negative pressure generated (i.e. the pressure lost). The pressure of loss is affected by the type of fertilizer and operating conditions, and the loss amount is 10%~75% of the original pressure. When purchasing, try to buy a fertilizer spreader with low-pressure loss. Due to the difference in the manufacturing process, the pressure loss value of different manufacturers of the same product varies greatly. The Venturi fertilizer applicator has the significant advantage of not requiring external energy sources. The cost of absorbing fertilizer from the open fertilizer tank is small, the fertilizer absorption range is large, the operation is simple, the wear rate is low, the installation is simple, it is easy to move, it is suitable for automation, the nutrient concentration is uniform and the corrosion resistance is strong. The disadvantage is that the pressure loss is large, and the amount of fertilizer absorbed is affected by pressure fluctuations.

- Gravity self-pressure fertilization method

In the application of gravity drip irrigation or micro-sprinkler irrigation, the gravity self-pressure fertilization method can be used. In orchards or tea plantations in the hilly hills of southern China, mountain springs or reservoirs that pump water from the foot of the mountain to a high place are often used. Usually, an open fertilizer pool is established next to the pool higher than the liquid level of the pool, the volume of the pool is 0.5~2.0 m”, which can be square or round, which is convenient for stirring and dissolving fertilizer. A pipe for the outflow of fertilizer liquid is installed at the bottom of the pool, and a PVC ball valve is installed at the outlet, which is connected to the outlet pipe of the reservoir. The pool is covered with 20~30 cm large pipe (such as 75 mm into 90 mm PVC pipe), and the pipe inlet is wrapped with 100~120 mesh nylon mesh. When fertilizing, calculate the total amount of fertilizer required in each round of irrigation area, pour it into the fertilizer pool, add water to dissolve, or dissolve it and pour it directly. Open the valve of the main pipe and start irrigating. Then the pipe of the fertilizer pond is opened, and the fertilizer liquid is diluted by the water flow of the main pipe and brought into the irrigation system. By adjusting the opening and closing position of the ball valve, the fertilization speed can be controlled. When the level of the reservoir does not change much (usually pumping water to the pool while dripping irrigation), the rate of fertilization can be fairly stable and maintain a constant nutrient concentration. At the end of fertilization, irrigation is continued for a while to flush the pipes. Usually, the fertilizer pond is built with cement to be strong and durable, and the cost is low. It can also be directly used as a fertilizer mixing tank with plastic barrels. To apply gravity self-pressure irrigation and fertilization, the fertilizer pool and the reservoir must be separated, and the two cannot be shared.

In the application of the gravity fertilization method in multiple orchard experiments, users reported that the operation was simple, the fertilization speed was fast and the fertilization was uniform, saving labor. When the reservoir water source is sufficient, proportional fertilization can be achieved. Equipment such as fertilizer tanks are installed in the field and are vulnerable to theft. The gravity fertilization method uses cement pools, which are not at risk of theft and are durable. The disadvantage is that the fertilizer spreading device is built at the highest part of the terrain of the orchard or tea plantation, which makes it slightly inconvenient to transport fertilizer.

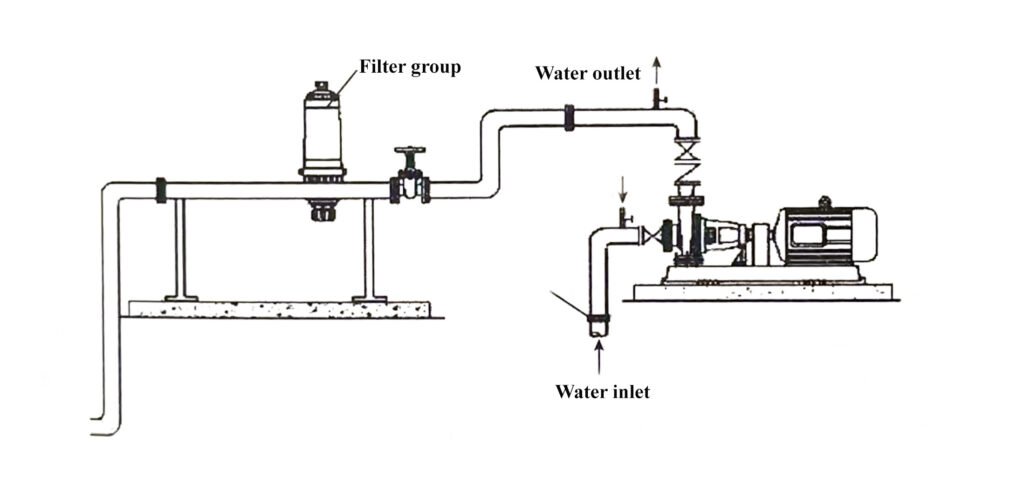

- Pumping fertilization method

The pump-suction fertilization method is the use of centrifugal pumps to suck the fertilizer solution into the pipeline system, which is suitable for fertilization methods in any area. In order to prevent the fertilizer solution from pouring into the pool and contaminating the water source, a check valve can be installed behind the suction pipe. Often on the inlet bag of the fertilizer suction pipe, a 100~120 mesh filter (stainless steel or nylon) is to prevent impurities from entering the pipeline. The advantages of this method are that there is no need for external power, a simple structure, and convenient operation. Fertilizer solutions can be held in open containers. When fertilizing, the fertilization speed can be controlled by adjusting the valve on the fertilizer liquid pipe. The disadvantage is that the water level of the water source cannot be lower than 10m from the pump inlet. When fertilizing fertilizer, someone should take care of it, and immediately close the valve on the fertilizer suction pipe when the fertilizer liquid is almost finished, otherwise it will suck in air and affect the operation of the pump. This method is simple to operate, fast and simple to implement. When the water pressure is constant, proportional fertilization can be achieved.

- Pumping fertilizer method

Fertilization in pressurized pipelines should be carried out by pumping fertilizer. Plunger pumps commonly used for pesticide spraying or general water pumps can be used. The injection port can be anywhere on the pipe. The pressure at which the fertilizer solution is injected is required to be greater than the pressure of the water flow in the pipeline. The fertilizer injection speed of this method is easy to adjust, the method is simple and the operation is convenient.